Slim Autoclave

Slim Autoclave

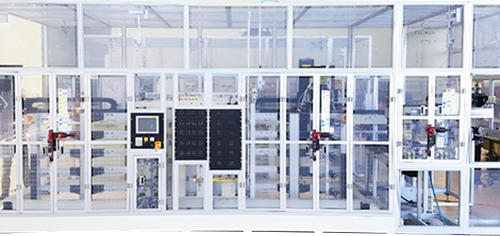

Slim autoclave has been in production since 2010 and are supplied to numerous

domestic and international display manufacturers. Designed to remove bubbles between films

these autoclaves cater to a diverse range of display sizes,

from small LCDs to ultra-large 100-inch+ TVs. Optimized for in-line processes,

they eliminate the need for separate return logistics and offer versatile process design capabilities.

Slim autoclave : single-direction, single-row

This Slim autoclave is specifically designed for processing small-sized displays, including watches and smartphones

Capable of accommodating diverse tact times

it enables individual tray tracking for each products within each chambers

Ensuring optimal quality through the uniform distribution of temperature and pressure

This versatile autoclave is suitable for a wide range of applications.

Slim autoclave : single-direction, two-rows

Designed for medium to large-sized displays

flexible configuration options for rows and columns to accommodate various tact times and space constraints

Ensuring optimal quality through the uniform distribution of temperature and pressure

This versatile autoclave is suitable for a wide range of applications.

Slim autoclave : single-direction, four-rows

Primarily installed in ultra-large display processes

Various logistics configurations are possible through consultations

Ensuring optimal quality through the uniform distribution of temperature and pressure

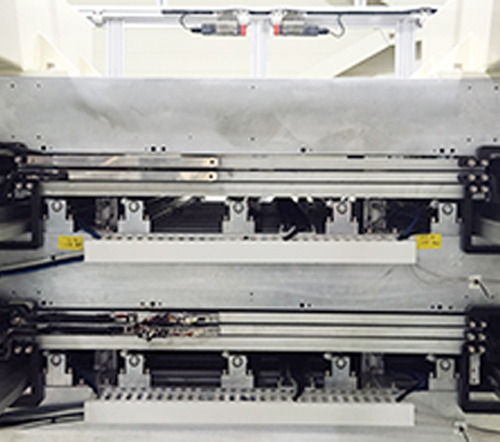

Slim autoclave : single-direction, each chambers with three slides

This autoclave simultaneously pressurizes and heats multiple slides within a single steel Chamber

reduces weight and cost by eliminating the need for a steel chamber unit.

The increased number of product-loaded slides allows for flexible tact times

With a footprint half the size of traditional models, it simplifies process layout

Ensuring optimal quality through the uniform distribution of temperature and pressure

Slim autoclave : double-sided opening, single-row

Primarily used for degassing small-sized components

The front-to-back sliding mechanism facilitates easy loading and unloading

Its compact design simplifies integration into existing production lines

Ensuring optimal quality through the uniform distribution of temperature and pressure

Naver Blog

Naver Blog

Youtube

Youtube

Instagram

Instagram

Facebook

Facebook

Tiktok

Tiktok